A New Vision for Furniture Packaging: Beyond the Brown Box

Jack Young

- Last Updated: 17 June 2025

Table of Contents

Key Takeaways – A New Vision for Furniture Packaging

- Regulatory changes (like Extended Producer Responsibility) are forcing industries to rethink packaging, focusing on sustainability and recyclability to avoid higher costs and penalties.

- The rise of direct-to-consumer (D2C) sales means packaging is now a core part of the customer experience and brand perception, not just a logistics component.

- Traditional packaging methods (tape, flimsy boxes, excessive foam) increase damage, complicate returns, and undermine perceived product value.

- Innovative designs, such as the lift-off, honeycomb box, offer superior protection, easier unboxing, and more sustainable materials, addressing both practical and psychological needs.

- Improved packaging enhances accountability by making damage sources clear, streamlining returns, and motivating better quality control across the supply chain.

- Investing in customer-centric, sustainable packaging is a strategic move that can turn regulatory risk into a competitive advantage.

TLDR - Core Summary: Reimagining the Brown Box

New regulations and rising customer expectations are making traditional furniture packaging obsolete. “Good enough” brown boxes and excessive tape now create frustration for customers, delivery teams, and retailers alike. The proposed lift-off box design, using honeycomb materials, offers better protection, easier returns, and a more satisfying unboxing experience, helping retailers meet sustainability targets, reduce costs, and build stronger brands in the direct-to-consumer era.

Why Packaging Innovation Can’t Wait

Peter Drucker famously urged leaders to “identify the future that has already happened”—to spot the signs of change in the present and act before the rest of the market catches up. Nowhere is this more relevant than in today’s packaging landscape, where the future is arriving faster than most furniture businesses realise.

The UK government’s push for sustainability is not just the usual political posturing but actively reshaping industry practices. Extended Producer Responsibility (EPR) regulations are tightening, shifting the full cost of packaging waste onto producers and importers. Starting in 2025, businesses will be charged not only for the volume of packaging they put on the market, but also for the recyclability and environmental impact of every material they use. The days of relying on lightweight but unrecyclable foam corners and wraps are numbered. While these materials may seem to keep costs down today, their poor recyclability and negative environmental footprint will soon attract higher fees, new taxes, and growing consumer backlash.

The first EPR fee payments for large producers are due in October 2025, covering the period from April 2025 to March 2026. Producers and importers will receive invoices from October 2025, and we will likely see price increases from that point onward as these new costs are factored into product pricing.

This is classic Schumpeterian “creative destruction” in action. Old packaging models are being swept aside by regulatory disruption and shifting consumer expectations. The transition won’t be painless. There’s a real need for open discussion and a managed shift to sustainable alternatives.

But beyond cost reduction and sustainability, packaging redesign must address a key but often overlooked factor— the customer’s unboxing experience. As the market shifts toward direct-to-consumer (D2C) channels, such as drop shipping, the packaging itself becomes a core part of brand experience and customer satisfaction. Unlike traditional in-home delivery, where your team or a third-party partner can guide the unboxing, direct shipments put the entire experience and the all-important first impression squarely in the hands of the customer.

This shift brings new challenges. In D2C models, packages often pass through multiple handlers, many of whom are more concerned with delivery speed than with ensuring the product arrives in perfect condition or preserving the unboxing experience. Then there are the customers who typically open boxes quickly, often tearing through packaging without regard for reusability or return logistics. As a result, boxes and protective materials are rarely in their original condition if a product is returned, increasing costs under the 14-day return framework and complicating resale and sustainability efforts.

When a customer receives a piece of furniture packed in a flimsy 5mm corrugated cardboard box, with only a thin foam cover and a few foam corners for protection, what message does that send? If the box arrives scuffed and battered after passing through multiple handlers, it doesn’t just risk damage—it signals to the customer that the product inside isn’t worth better packaging. In effect, it undermines the value of the product and leaves the customer questioning whether it was worth the money they paid.

If you want your customers to feel confident in their purchase, your packaging must reflect the quality of what’s inside. Investing in more robust and sustainable packaging is not just about compliance or cost; it’s about reinforcing your brand’s promise and ensuring customers feel they’ve made a worthwhile investment.

The signs of the future are here. The only question is whether we’ll recognise them in time to turn regulatory risk into competitive advantage—or get boxed in by the past.

Exploring the Next Generation of Packaging

I’ll share my thoughts on the future direction of cardboard box design and its support systems—balancing sustainability, cost, and customer experience. The design I propose is theoretical at this stage. It hasn’t yet been fully tested in the field. While I believe it holds real promise, like any innovation, it will need to be refined and validated through practical trials.

New Furniture Packaging Design and Construction

“An idea is nothing more nor less than a new combination of old elements.”

—James Webb Young, A Technique for Producing Ideas (1939)

Good Compression Resistance

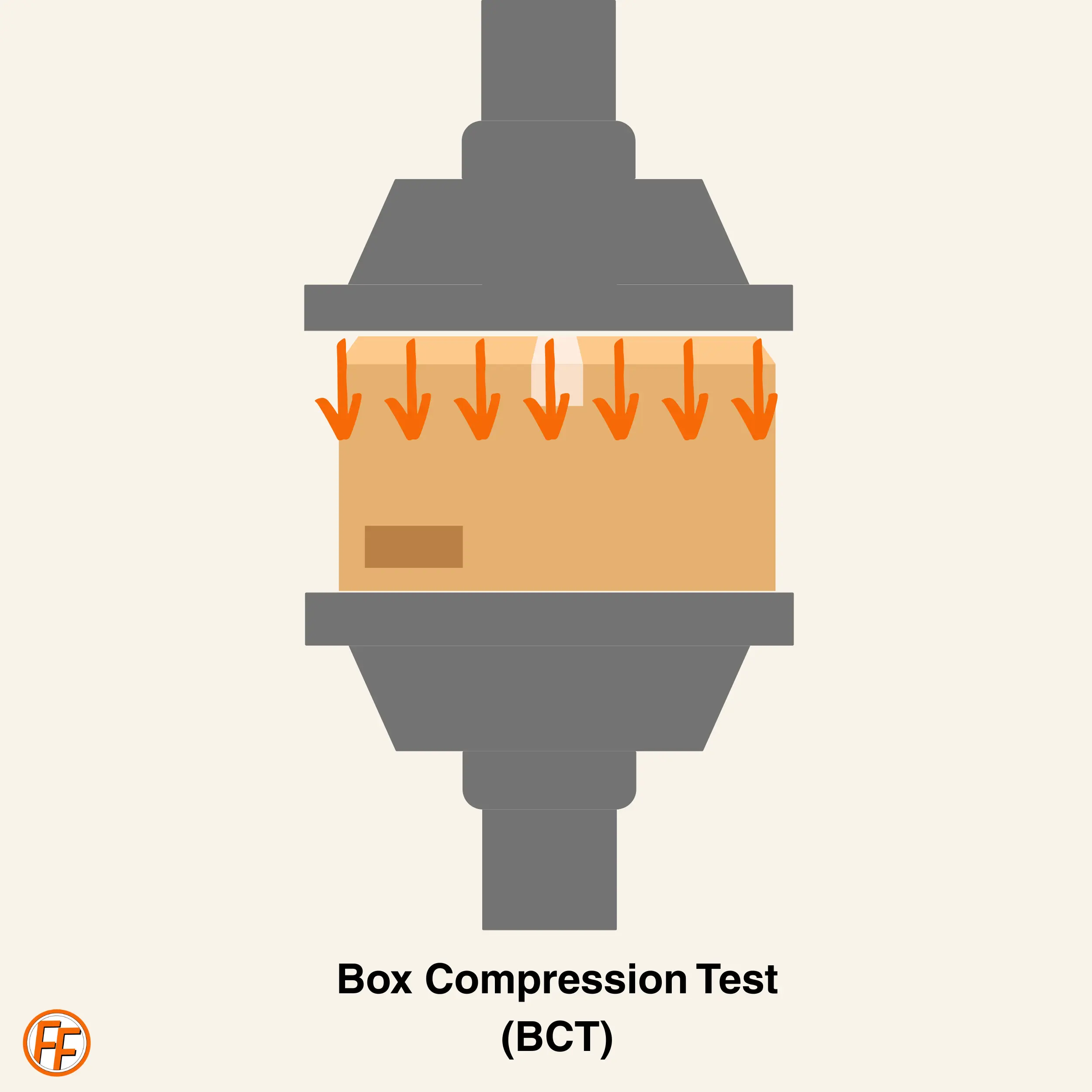

At this stage, it’s important to clarify the two main aspects of compression that determine how well a box’s construction meets the needs of the industry.

In simple terms, compression resistance is a material’s ability to withstand forces pushing inward or downward without collapsing, deforming, or damaging the contents. Think of it as the packaging’s “squishability”. Good compression resistance means the box won’t easily give way under pressure.

This resistance is essential when boxes are stacked during storage or transit. The packaging industry measures this with the Box Compression Test (BCT), which determines the maximum load a box can bear before it crushes or deforms. Strong compression resistance ensures a box can support the weight of other packages stacked on top, whether in a warehouse or inside a delivery lorry, without buckling or collapsing.

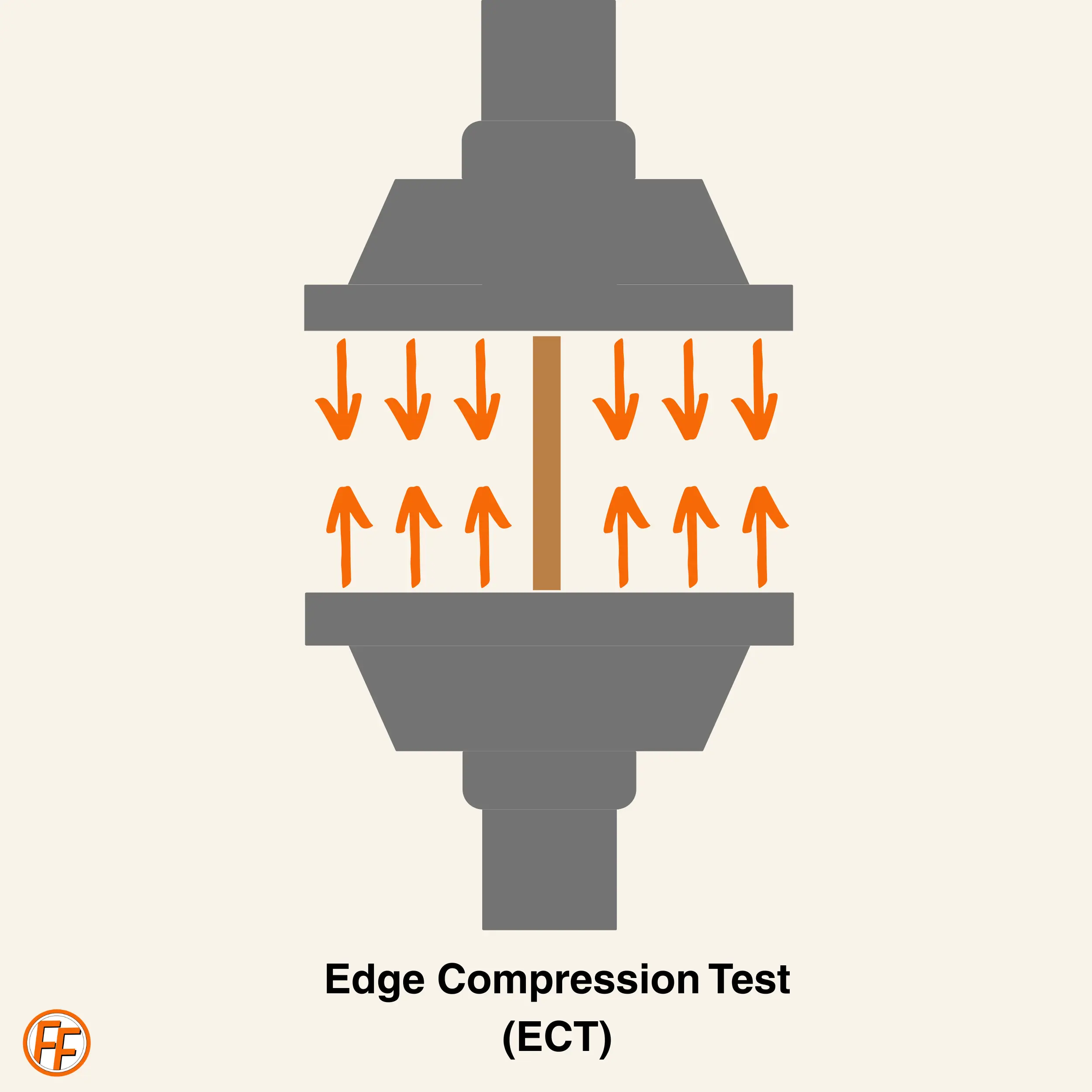

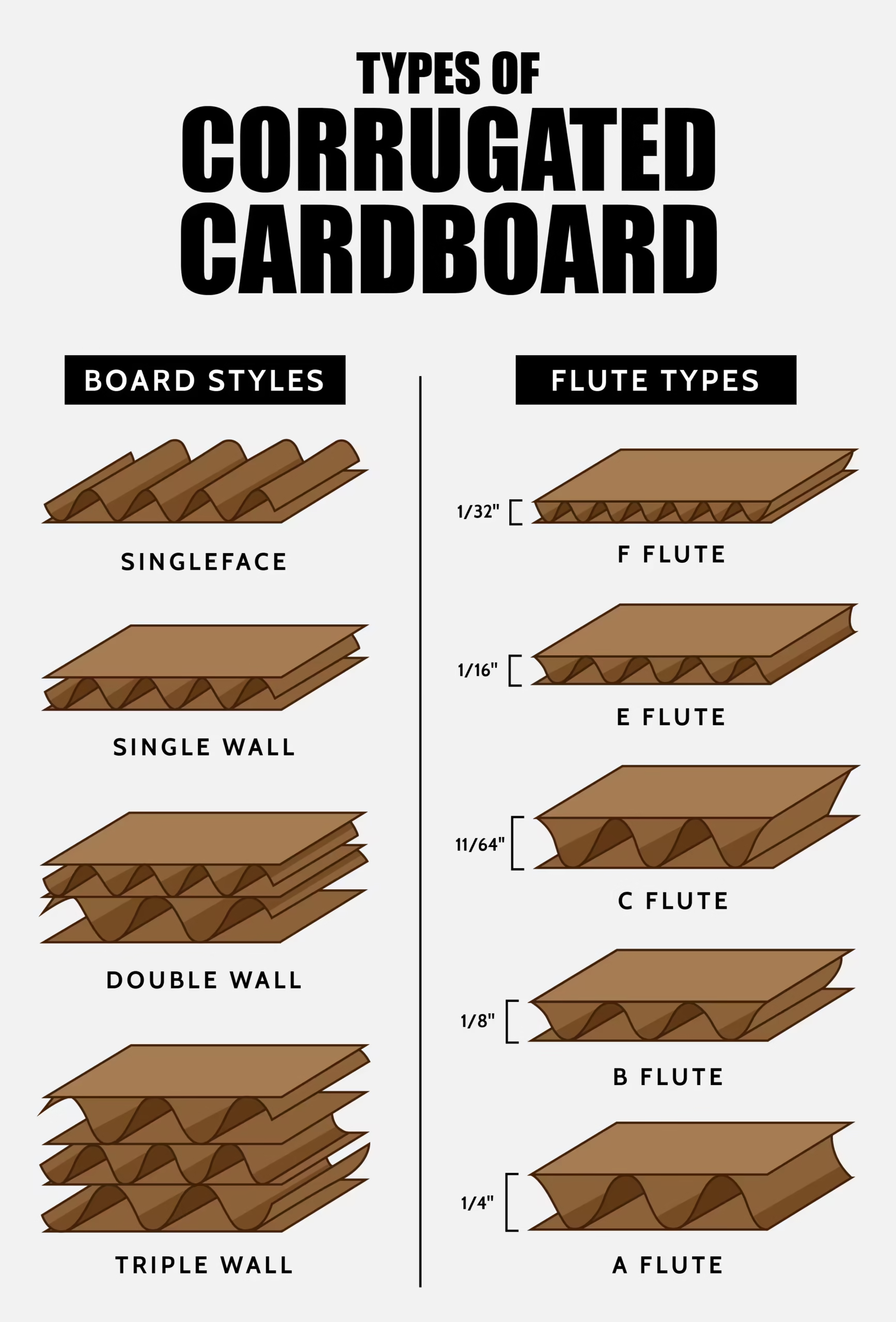

Another important measure is the Edge Crush Test (ECT), which assesses how well the edges of corrugated cardboard resist vertical pressure—an indicator of how the box will perform when stacked and handled.

Beyond static weight, packaging must also absorb dynamic forces, like bumps, drops, and vibrations, encountered during handling and shipping. Effective compression resistance helps prevent these shocks from damaging the product inside, maintaining structural integrity. For example, if a lorry hits a pothole, the sudden downward force should be absorbed by the box, not transferred to the delicate legs of a console table or the glass of a display cabinet.

The Box design itself significantly impacts compression resistance. Factors such as box dimensions, the ratio of length to width to height, and the method of sealing all affect overall strength. For instance, a tall, narrow box will typically have less compression resistance than a short, wide one made from the same materials, due to a greater tendency to buckle.

Ultimately, the primary goal of packaging is to protect the product. Poor compression resistance leads directly to product damage, scratches, dents, breakages, or warping, which results in costly returns, refunds, and a damaged brand reputation.

The Double-Walled Honeycomb Box

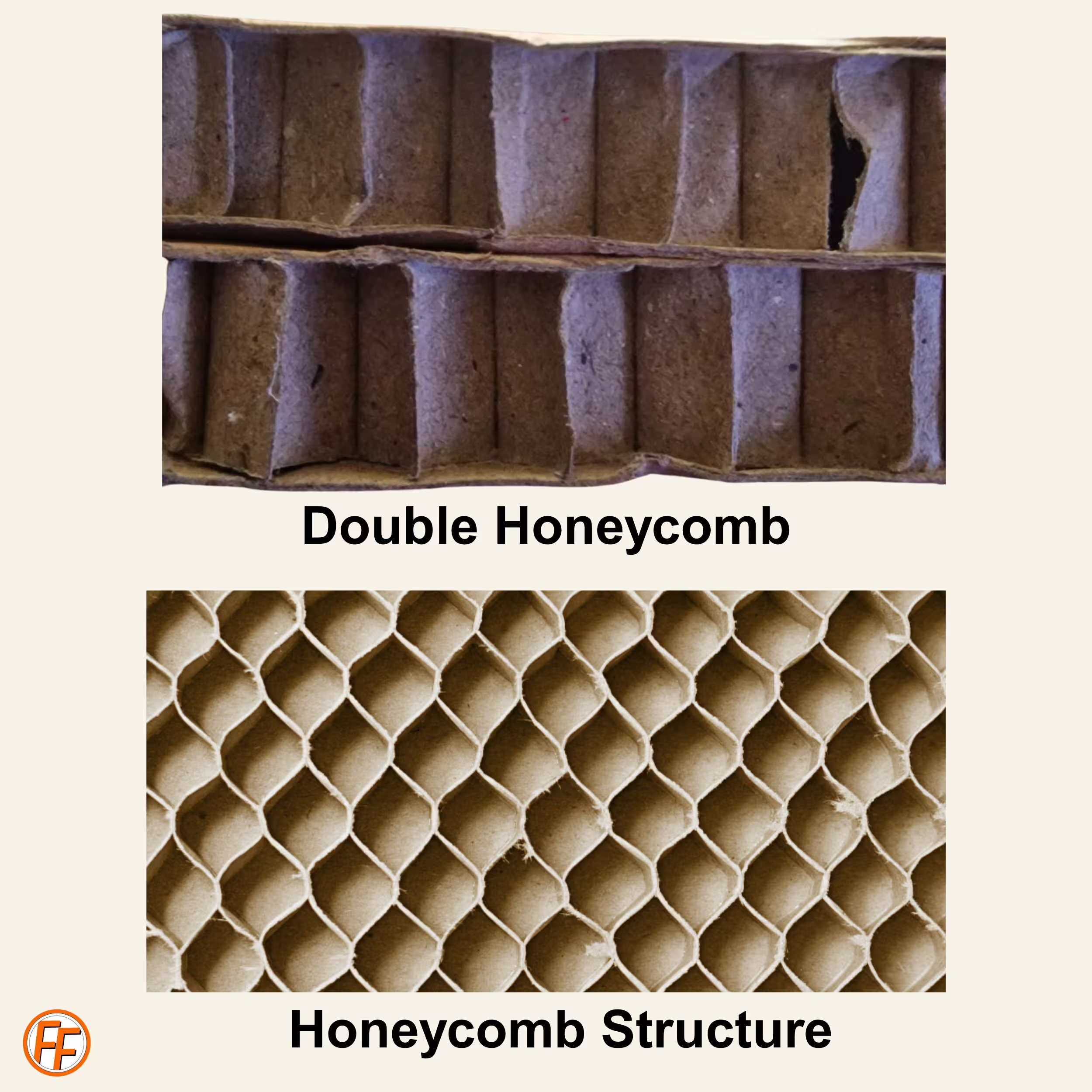

My initial concept was a double-walled honeycomb box, designed to offer superior protection against transit damage compared to standard single-wall boxes.

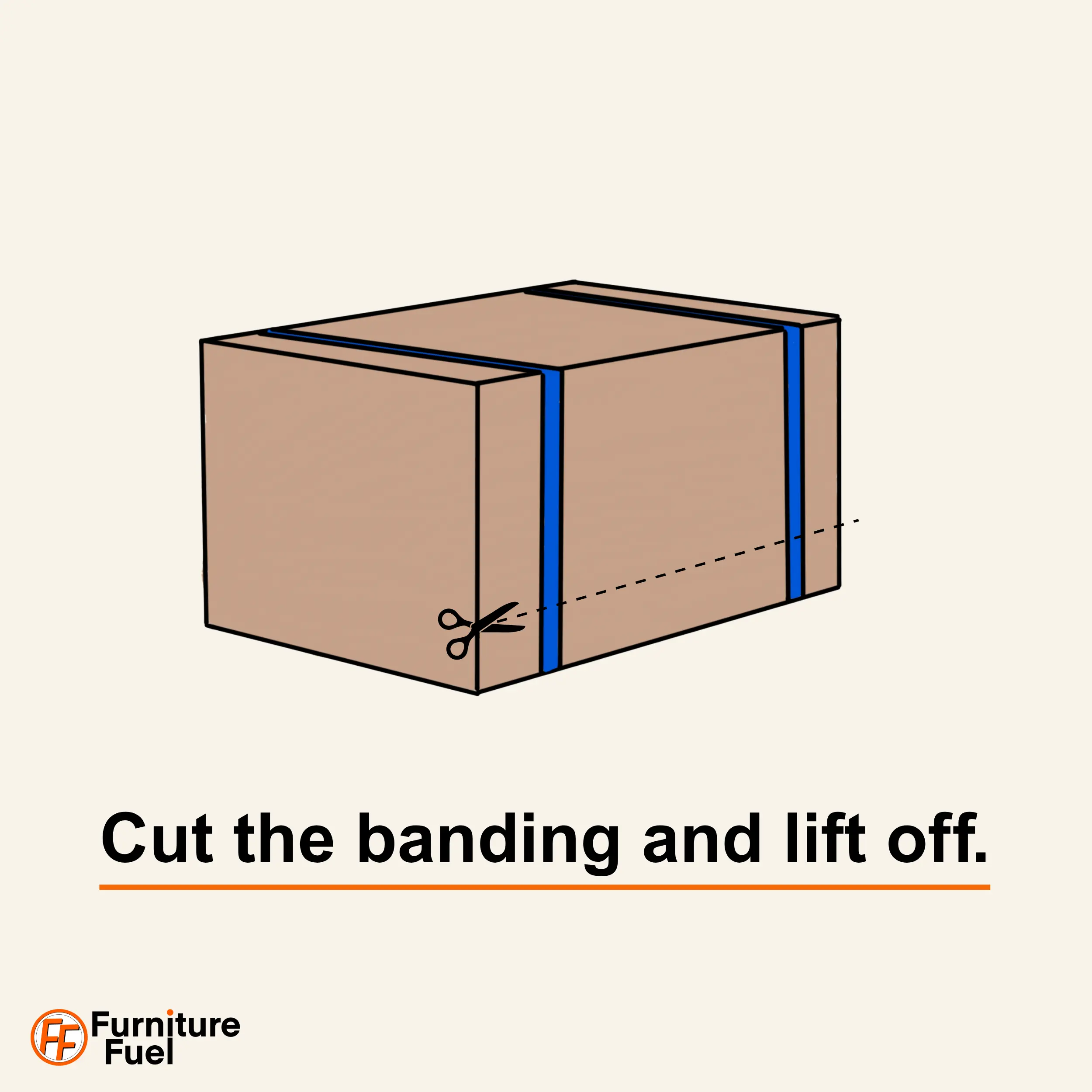

This design features a “lift-off” construction—think of it as a reverse shoebox—which addresses a common pain point: customers often destroy packaging upon arrival, making returns difficult and costly. A lift-off box helps preserve the packaging for potential returns, reducing waste and streamlining the process.

Another advantage of the lift-off design is that it eliminates the risk of slice damage to the product from opening the box with a knife or scissors. No matter how many “do not use sharp objects” warnings are given, sharp tools are still used (I know from experience, though, so far, with a perfect no-damage record!).

When first considering this design, I identified two major drawbacks. The first is storage. A double-walled honeycomb box is more complex and may not flat-pack as efficiently as simpler boxes, leading to higher storage requirements and increased warehousing costs. The second is the increased cost per unit. The extra materials required for a double-wall honeycomb structure would undoubtedly raise packaging costs. However, these costs could be offset by savings across the supply chain. Fewer damaged items mean fewer returns, less reverse logistics, and fewer replacement shipments. Reduced complaints about damaged goods also free up your customer service team to focus on other priorities. Ultimately, delivering an undamaged product in excellent condition enhances the customer experience and builds trust in your brand.

But these aren’t the only considerations. Let’s look at the technical performance:

Box Compression Test (BCT) of Honeycomb vs Corrugated

Due to its hexagonal, cellular structure, honeycomb cardboard is inherently designed to distribute pressure evenly and resist crushing forces applied to its flat surfaces. It’s incredibly strong when pressed from above or below, acting like a network of tiny, interconnected columns that provide immense load-bearing capacity. Honeycomb often has significantly higher flat compressive strength than corrugated, sometimes double or more for the same material thickness.

Corrugated cardboard also provides good compression resistance, especially when the flutes are vertical. However, under very heavy or prolonged loads, the flutes can buckle or flatten, leading to reduced strength over time.

Edge Crush Resistance (ECT) of Honeycomb vs Corrugated

This is where corrugated cardboard excels. The arched flutes are engineered to provide rigidity and resist crushing when pressure is applied along the edge, which is why ECT is a standard measure for corrugated cardboard and a key indicator of stacking performance.

Honeycomb’s strength is primarily in flat compression. While it offers some edge compression, it generally does not match the edge crush resistance of strong corrugated board of similar thickness, especially if the pressure isn’t optimally aligned with the hexagonal structure. For example, when offloading a box from a truck, it’s often rested on its edge before being moved, which can be a vulnerability for honeycomb.

An additional benefit of honeycomb is that its compression resistance is less affected by humidity compared to standard corrugated. High humidity can weaken corrugated cardboard, reducing its ability to withstand loads. Honeycomb, being less susceptible to moisture, can be advantageous for furniture stored or shipped in humid conditions.

How the Box Stays Together

Originally, I considered using plastic banding to secure the box. While the aim is for 100% sustainability and banding doesn’t fully align with this goal, polypropylene (PP) and polyester (PET) strapping can be recycled under the right conditions. However, this aspect would need further evaluation in the context of a fully sustainable solution.

The Unboxing Experience

A double-walled design elevates the perceived quality of the purchase, making the unboxing a memorable moment and tapping into the “peak-end rule” in buyer psychology. The process is simple: cut the two straps, lift off the lid, and reveal the product—no wrestling with tape or risking damage.

The peak-end rule is a psychological principle suggesting that people judge an experience largely based on how they felt at its most intense point and at its end, rather than the average of every moment. By ensuring the unboxing is smooth and satisfying, you leave a stronger, more positive impression—one that can influence future purchase decisions and brand loyalty.

With these benefits and flaws in mind, is there a way to design a box that achieves both high BCT and ECT compression while remaining 100% sustainable? I believe there is. A hybrid of old and new. The design would retain the lift-off feature, but the construction would differ.

There’s more to the lift-off design than just customer convenience, so it’s worth explaining why I believe it’s the best approach before introducing the hybrid construction.

Why the Lift-off Box May Be the Best Design

Imagine it’s delivery day for a customer who’s been eagerly awaiting their new sideboard. The delivery team arrives, and instead of wrestling with endless tape or risking damage with a knife, they simply cut the two external straps and lift off the lid—like opening a treasure chest. The product is revealed instantly, pristine and protected, making inspection effortless.

The lift-off design doesn’t just protect your product—it turns every delivery into a shareable moment. In an age where customers love to showcase their purchases online, a seamless, elegant unboxing experience can amplify your brand’s reach and reputation.

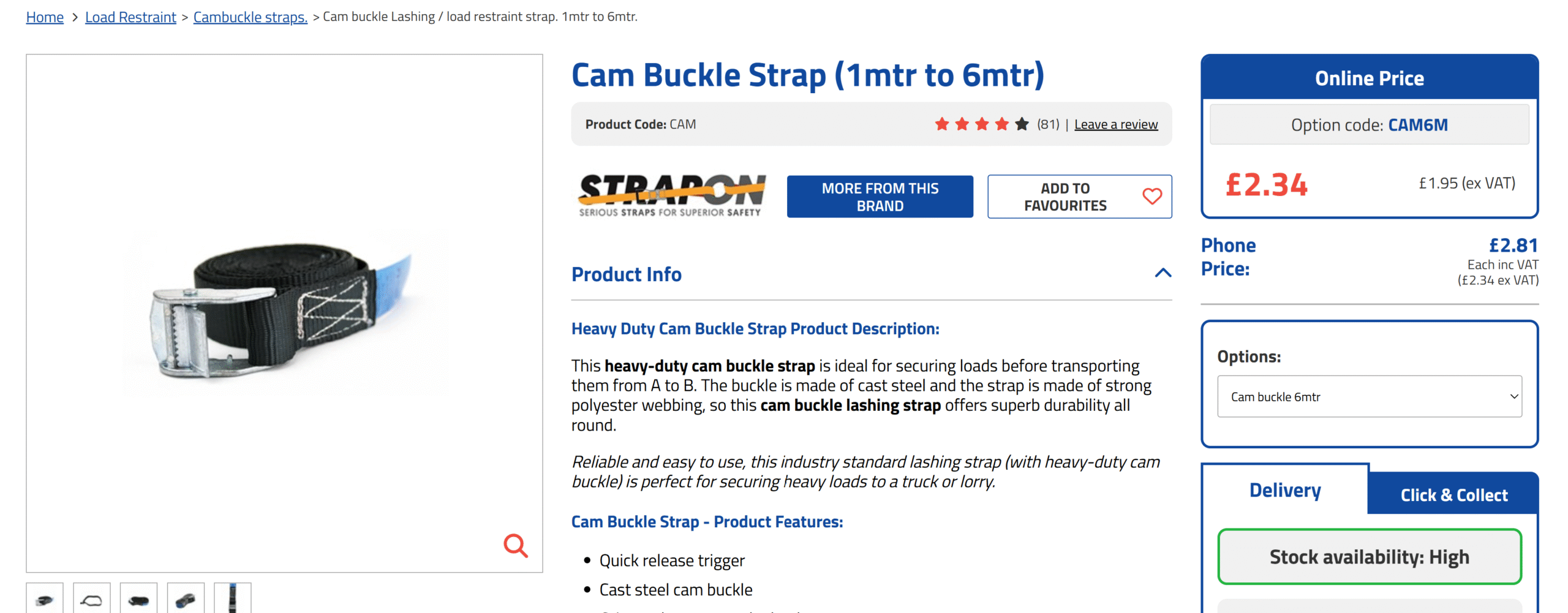

However, sometimes things go wrong. If there’s a problem, the team can quickly reseal the box—just put the lid back on and secure it with reusable cam buckle straps (not ratchet straps, but the type that thread through a buckle and pull tight). This keeps the original packaging intact for the return journey, eliminating mangled boxes, frantic searches for tape, and the need for banding machines on delivery vans.

Image source: Safety Lifting Gear

This simple lift-off design doesn’t just save time for the delivery crew. It’s beneficial for logistics partners as well. With fewer products damaged in transit, there are fewer claims and headaches for everyone involved. Over time, this reliability could even give businesses more negotiating power with courier companies. After all, who wouldn’t want to work with a retailer who makes their job easier and their bottom line healthier?

The benefits extend beyond logistics. If the box arrives immaculate but the sideboard inside has a scratch or dent, the untouched packaging makes it clear the issue didn’t occur during shipping—it’s a manufacturing defect. This transparency removes the “blame game” between supplier, courier, and retailer. Suppliers are motivated to tighten their quality control, knowing any issues are easily traceable. Accountability becomes straightforward, allowing everyone to focus on resolving the real problem rather than pointing fingers.

There is something quietly powerful about packaging that feels considered. It reassures the customer that care has been taken, not just in the product, but in every step of its journey. True simplicity in packaging isn’t the absence of features, but the thoughtful removal of friction. When a box opens effortlessly and the product is revealed without struggle, it communicates respect for the customer’s time and attention. The moment of unboxing becomes more than a transaction—it’s a small ceremony, a moment of delight and trust.

In the end, the lift-off box has the potential to transform the experience for customers, couriers, and suppliers alike. It’s a cleaner and ultimately more satisfying way to deliver quality products.

The Hybrid Furniture Box

The hybrid lift-off box design I propose combines the best attributes of modern packaging materials to deliver robust, sustainable protection for furniture.

The main body features a single wall of honeycomb, ensuring that the primary surfaces (top, bottom, and large sides) benefit from superior flat compression strength. This allows furniture to be stacked high without the box collapsing, providing reliable protection against crushing damage for heavy items like wardrobes or dining tables.

The external layer of the honeycomb would be a durable layer of robust laminated cardboard, enhancing resistance to puncture and abrasion. At the corners—critical impact points—the design incorporates traditional corrugated cardboard, ideally a strong double or triple wall variety. Corrugated corners provide excellent edge crush resistance and often outperform honeycomb for direct, concentrated impacts. This approach also adds rigidity and helps prevent racking (when a box distorts into a parallelogram shape), which can occur during handling or if a stack shifts.

Source: Image source unknown. Full attribution given when discovered.

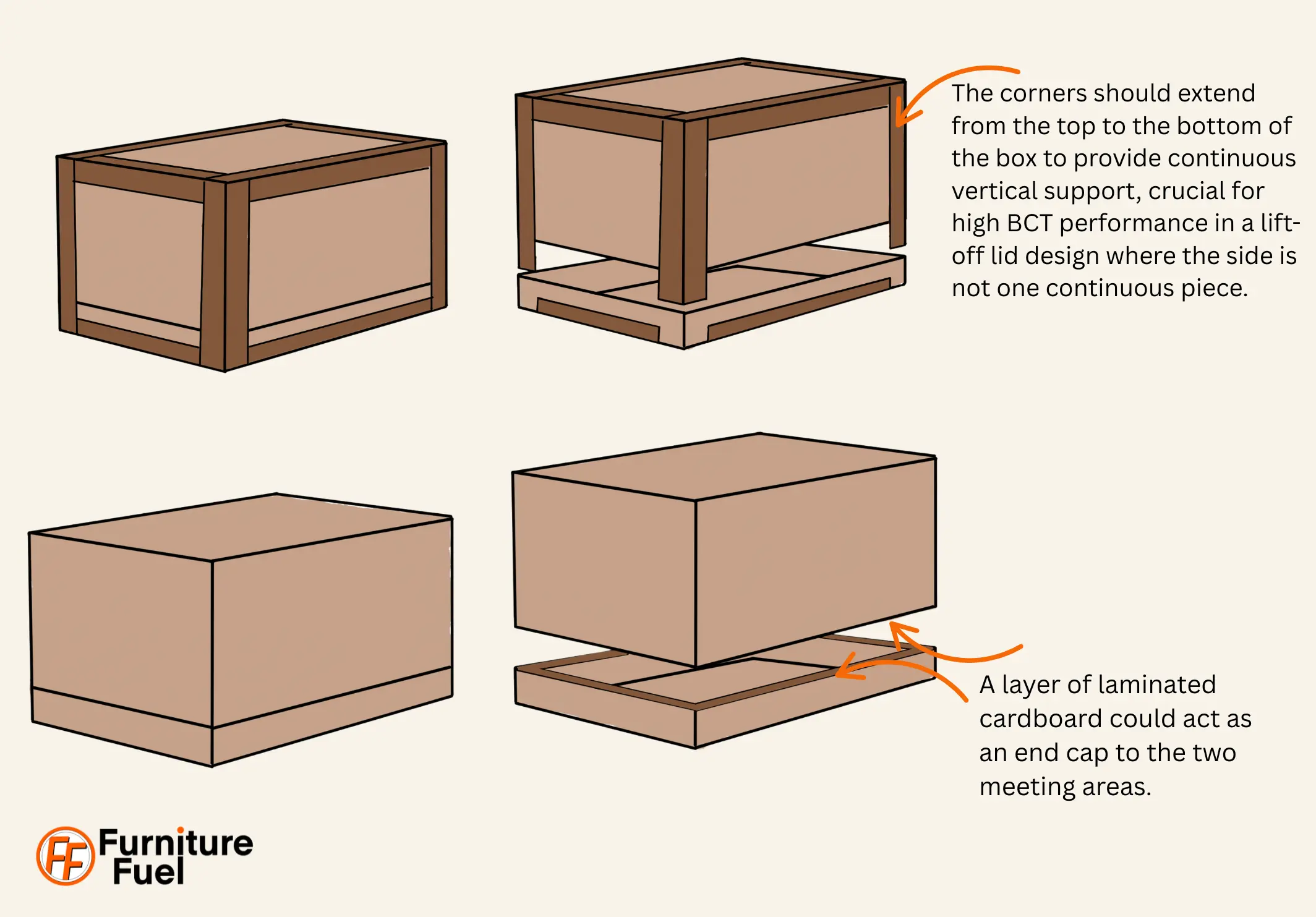

These corrugated corners could be glued onto the honeycomb structure, allowing for easy replacement and extending the life of the box. The corners should extend from the top to the bottom of the box to provide continuous vertical support, crucial for high BCT performance in a lift-off lid design where the side is not one continuous piece. This alleviates the weakness where the seam is a failure point under compression. Alternatively, or additionally, a layer of laminated cardboard could act as an end cap to the two meeting areas.

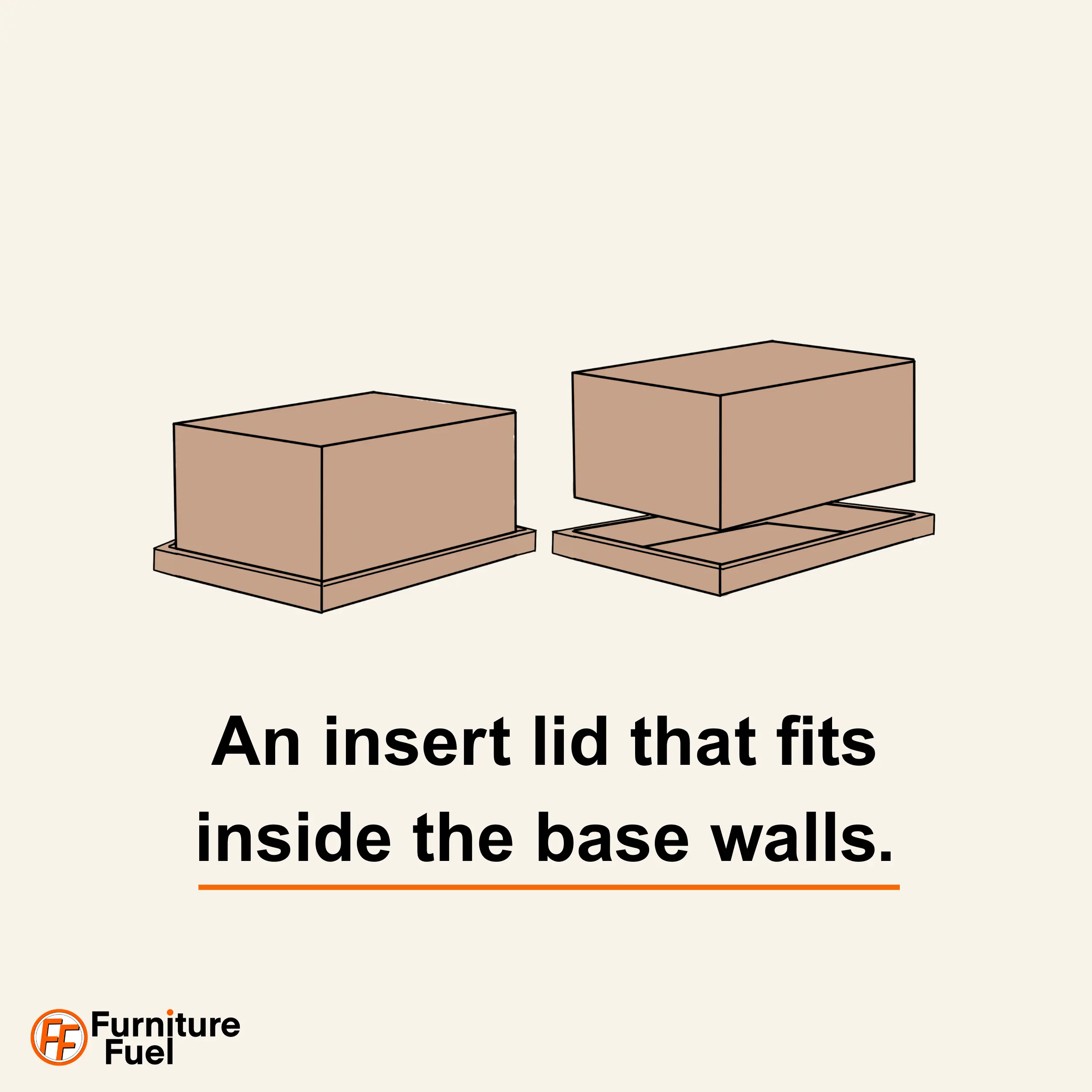

The lift-off lid could also be an insert lid that fits inside the base walls, ensuring the outer walls remain continuous and bear the stacking load, significantly improving BCT performance

The issue this creates is that the corners would not allow for the tape to run the full circumference of the box, joining the two parts seamlessly, so this would then need the banding to secure the top halves, reducing the sustainability.

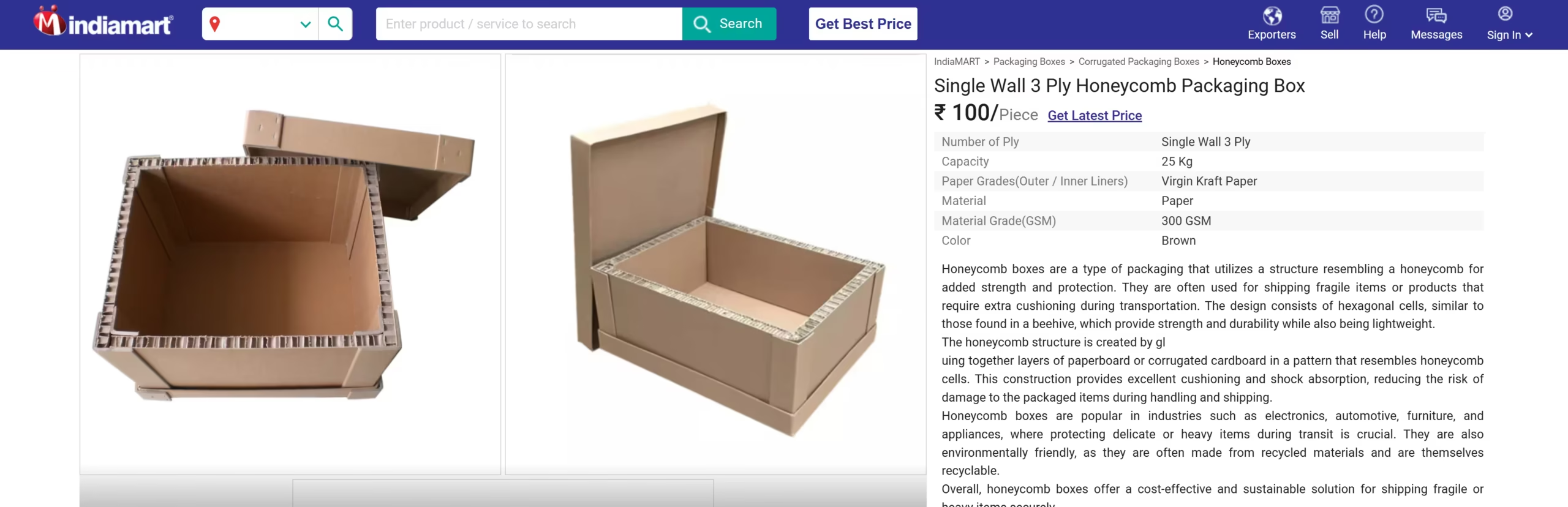

There are existing modular styles of construction, where the sides slide into hardened cardboard corners, with a separate lid and base. While this modular approach is easier to store and allows damaged parts to be swapped out, it can add time to the re-boxing process for delivery crews and customers. Although it shares some benefits with the lift-off design, the additional complexity may not deliver the same seamless unboxing experience.

Source: Indiamart

While researching reference photos, I noticed an alternative design. A full corrugated box with honeycomb inserts. This simpler approach could resolve some storage challenges and still provide robust protection. The lift-off design, however, remains superior in terms of user experience and ease of inspection.

Source: BEWI Packaging

It’s important to remember that the goal isn’t just to deliver a product in a flawless box. The real aim is to ensure the product itself arrives safely. If the outer box is damaged but the contents are pristine, it actually reinforces the customer’s trust. The retailer has clearly prioritised protecting the product. This attention to detail and care builds confidence in both the brand and the purchase.

Prototyping and real-world testing will be essential to ensure these designs meet both strength and usability standards.

Internal Support Packaging - Sustainable, Foam-Free Protection

While the hybrid honeycomb-corrugated box offers excellent structural protection against crushing and impact, it’s equally important to safeguard delicate furniture surfaces from scratches and scuffs caused by direct contact with cardboard. Cardboard’s slightly abrasive texture, combined with movement during transit, can leave unwanted marks on polished wood, painted finishes, glass, or upholstery. Traditionally, polyethylene foam has been used to prevent such damage, but its environmental drawbacks and tightening Extended Producer Responsibility (EPR) regulations make it an increasingly unsustainable—and potentially costly—choice.

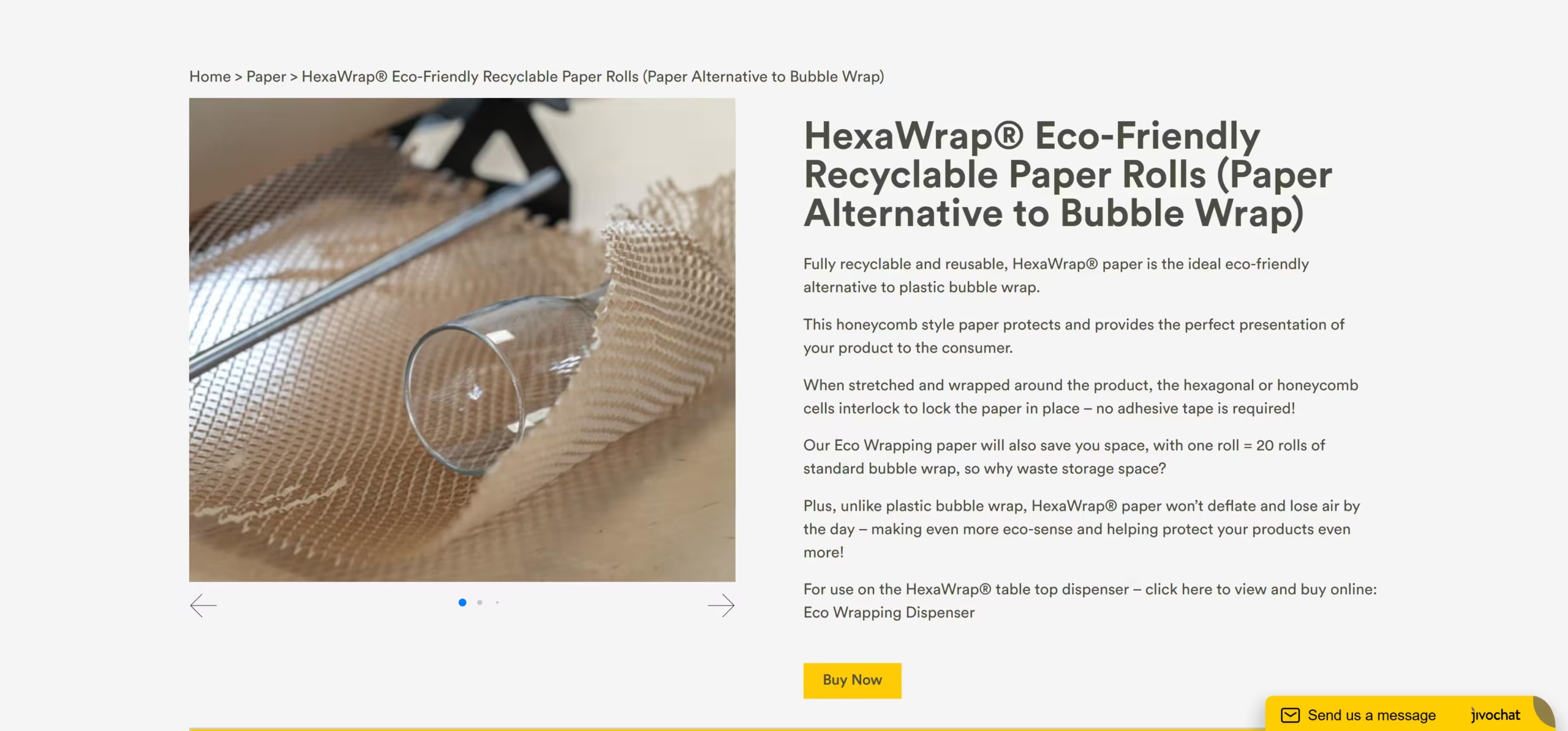

To move beyond foam, we need alternatives that provide effective surface protection while aligning with sustainability goals. Paper-based materials have emerged as promising substitutes. For example, paper “bubble wrap” variants, such as HexaWrap or paper bubble, replicate the cushioning effect of plastic bubble wrap but are made entirely from recycled paper, making them fully recyclable and compostable.

Source: Wessex Packaging

Another option is recycled kraft or crepe paper rolls, which offer a flexible, non-abrasive buffer directly against furniture surfaces. While kraft paper provides less cushioning than bubble-like materials, it is widely recyclable, biodegradable, and cost-effective, making it best suited for scratch prevention rather than shock absorption.

QuiltWrap is another solution, specifically engineered for gentle, padded protection. Usually made from recycled fibres and featuring a quilted, fabric-like texture, it is well-suited for protecting delicate surfaces by minimising the risk of micro-abrasions, scuffs, or pressure marks.

Source: Wessex Packaging

As the search for truly sustainable, foam-free internal packaging continues, among the options is the use of thin wool blankets as protective wraps inside furniture boxes, which presents a unique proposition. Wool, a naturally renewable and biodegradable material, offers a unique combination of gentleness, resilience, and environmental responsibility that few other materials can match.

Unlike traditional paper-based wraps, which—while sustainable—can sometimes cause micro-abrasions on highly polished wood or delicate leather, wool’s soft, flexible fibres provide a superior barrier against scratches and scuffs. Its cushioning properties also help absorb shock and movement during transit, making it ideal for protecting furniture finishes.

The advantages of a wool blanket extend beyond protection. Including a thin wool blanket as part of the packaging could add value for the customer. Rather than being discarded, it can be repurposed as a dust cover or protective layer for future moves. Of course, storage is a consideration, and some customers may choose to dispose of the blanket. However, even in this scenario, wool’s environmental impact is minimal. As a natural fibre, it will biodegrade over time, unlike synthetic foams or plastics that persist in landfills for decades. For the unboxing experience, a slight redesign might be needed, as the standard grey moving blankets lack the visual appeal that enhances first impressions.

Among these options, paper-based bubble wrap, HexaWrap or QuiltWrap stands out as the most practical, sustainable internal support material. These solutions balance cushioning performance with recyclability and composability, offering protection against scratches while meeting rising environmental expectations

The Role of Corner Protection: Sustainable Shock Absorption

As we’ve discussed, the corners of a box are its most vulnerable points, especially during drops or rough handling. Traditionally, foam corner protectors have been the go-to solution, acting as shock absorbers that compress and dissipate energy, reducing the force transferred to the product. However, as the industry moves away from foam, it’s essential to find sustainable alternatives that still provide effective shock absorption.

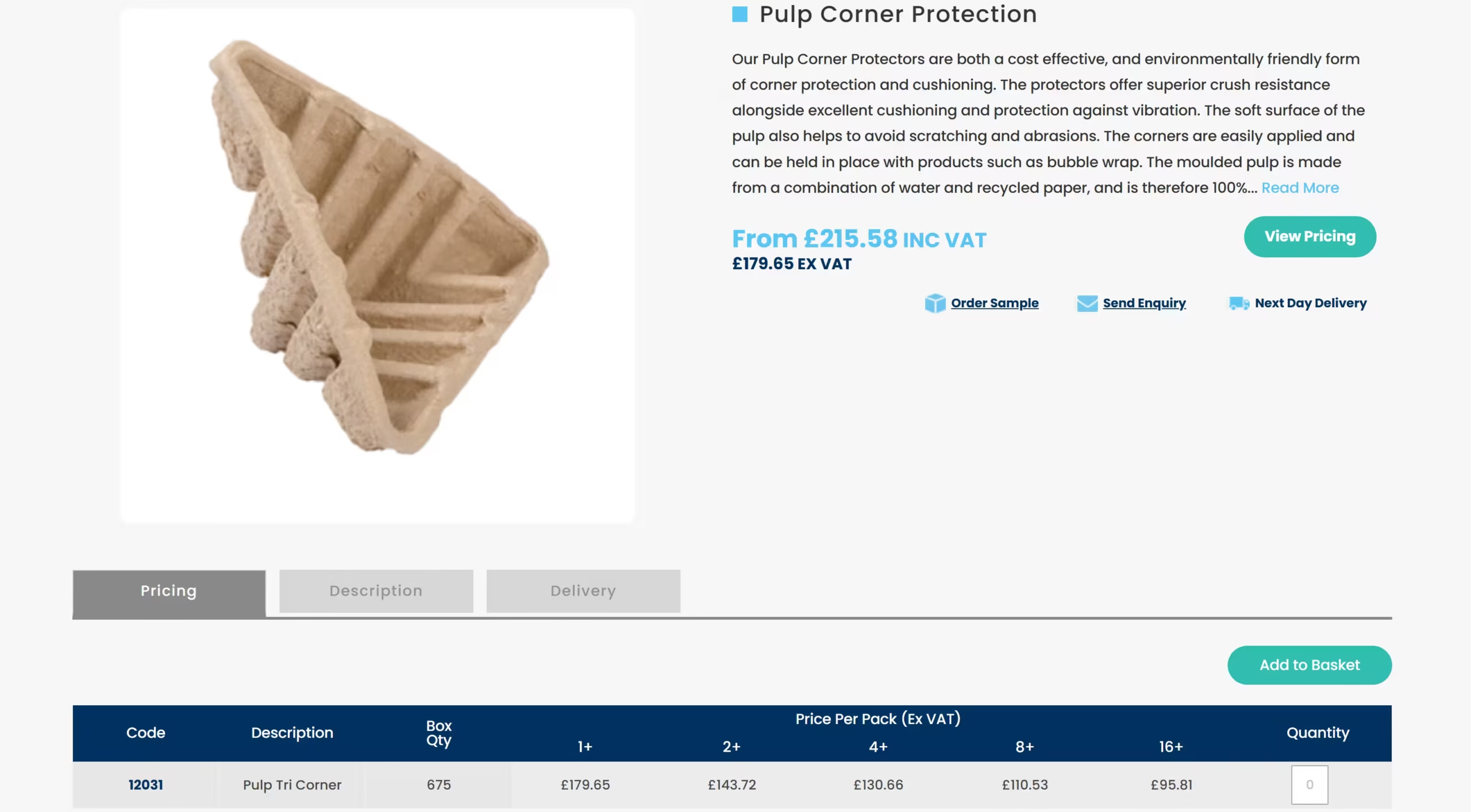

One solution is the use of moulded pulp or reinforced cardboard corner protectors. Made from recycled paper pulp or layered cardboard, these protectors are engineered to deform under stress, absorbing and dispersing impact energy much like foam. They are fully recyclable and biodegradable, making them a strong contender.

Source: UKPackaging

For even greater protection, a layered approach may be more effective. Wrapping the product in QuiltWrap creates a soft, non-abrasive barrier that shields surfaces from scratches and scuffs. Adding an outer layer of paper bubble wrap enhances cushioning and further absorbs shocks, particularly at the corners. While neither material alone matches the compressibility of thick foam, together they provide a robust, sustainable barrier during transit.

It’s important to be realistic, however. Even the best corner protection has its limits. If a piece of furniture is dropped from a significant height, no packaging material—foam, pulp, or paper—can guarantee complete protection. The primary role of corner protection is to safeguard against the bumps, jolts, and minor impacts that occur during normal movement and handling.

By combining moulded pulp or layered QuiltWrap and paper bubble wrap, you can achieve a level of protection comparable to traditional foam, without compromising on sustainability or customer experience. But again, as with any packaging innovation, these solutions require prototyping and real-world testing to validate their effectiveness.

Reimagining the Brown Box

Adopting innovative packaging—such as the hybrid lift-off box—is not without its challenges, but the potential rewards far outweigh the initial hurdles.

While the upfront costs may appear significant, they should be seen as a strategic investment. Reduced product damage, fewer returns, and improved customer satisfaction can deliver substantial long-term savings and enhance brand value. Better packaging also helps pinpoint and reduce manufacturing defects, streamlining operations and minimising waste. These factors collectively contribute to a strong return on investment, especially for high-value or damage-prone products.

Economies of scale will play a crucial role as adoption increases and production volumes rise. As more companies embrace advanced packaging, unit costs and manufacturing complexity are likely to decrease, making these solutions accessible to a broader range of products and businesses. At the same time, extended producer responsibility (EPR) regulations and shifting geopolitical landscapes are driving governments to mandate sustainable, recyclable, and efficient packaging. This regulatory pressure will only accelerate industry adaptation, making hybrid and sustainable designs not just a competitive advantage but a necessity.

It’s important to clarify that this is not a one-size-fits-all solution. The hybrid model is best suited for products where the benefits of enhanced protection and customer experience justify the investment. For other items, simplified versions inspired by the same principles can be developed, enabling a tiered packaging strategy that balances cost, sustainability, and performance across a diverse product range.

Storage and bulkiness are valid logistical concerns, but they are not insurmountable. Addressing these challenges will require ongoing innovation and collaboration.

Packaging is not just a box—it’s a strategic part of your product and your brand. By investing in protection, you’re investing in your reputation, your operations, and your customers’ experience.

The drive for change must come from both forward-thinking importers and suppliers. Importers, who bear the direct cost of damage, have the leverage to demand better packaging from their partners. Meanwhile, manufacturers who embrace superior packaging can set themselves apart and improve their own quality control.

However, collaboration across the entire industry is essential. A coordinated effort involving retailers, delivery partners, and manufacturers is needed to understand how loading, unloading, storage, and movement of goods take place across the supply chain, from large retailers to small independents. Gathering data on the journey from manufacturer to home is vital because the journey matters as much as the destination.

All of this requires thought, and so it requires time. We need to act now in order to transition the industry to meet to demands of the future—today.